Superior rentals squeeze tools: practical applications you should know

Wiki Article

A Comprehensive Overview to the Various Sorts Of Oil Field Equipment and Pipeline Equipment Available

The oil and gas industry relies heavily on specialized tools for effective extraction and transport. Various sorts of machinery, from drilling rigs to storage space tanks, play crucial functions in this intricate procedure. Each tool offers distinctive features that add to total operational success. Understanding these elements is essential for anyone included in the field. As the market evolves, so also do the modern technologies that support it. What developments are on the perspective?

Drilling Rigs: The Backbone of Oil Expedition

Drilling rigs serve as the essential equipment in the domain name of oil exploration, enabling companies to gain access to hydrocarbon reserves buried deep under the Earth's surface area. These rigs are available in various types, consisting of land rigs, offshore rigs, and mobile systems, each made to run in certain settings. Outfitted with advanced innovation, piercing rigs can permeate geological formations with accuracy, making certain effective resource removal. The structural honesty and functional capacities of these rigs are crucial, as they need to stand up to severe conditions and significant pressures. The option of a boring gear influences the general project expense and timeline, making it a crucial consideration for oil companies seeking to enhance their expedition initiatives and maximize efficiency in their operations.Pumps: Vital for Liquid Movement

In the oil removal process, the duty of pumps is significant, helping with the activity of liquids throughout various stages of production. Pumps are important for delivering crude oil, water, and other fluids from below ground storage tanks to the surface area and after that with pipelines to refineries. They are available in different types, including centrifugal, favorable displacement, and completely submersible pumps, each serving details objectives based on the fluid characteristics and functional requirements. Centrifugal pumps are commonly used for their efficiency in high-flow applications, while positive displacement pumps stand out in managing viscous fluids. The choice of pump influences total performance, functional security, and maintenance prices. Correct selection and upkeep of pumps are important for optimizing production and reducing downtime in oil field operations.Valves: Controlling Circulation and Pressure

Shutoffs play a crucial duty in taking care of the circulation and stress of fluids within oil fields and pipes. Different sorts of shutoffs offer distinctive applications, each made to accomplish particular features basic for reliable procedure - Superior rentals squeeze tools. Understanding the characteristics and uses these valves is necessary for enhancing system performance and safety

Kinds of Valves

Important elements in oil field procedures, valves play a critical role in regulating the flow and pressure of liquids within pipelines and equipment. Numerous sorts of valves are used to satisfy the diverse requirements of oil and gas manufacturing. Usual kinds consist of gate valves, which give a straight-line flow and marginal pressure decline; world shutoffs, recognized for their throttling capabilities; and sphere valves, acknowledged for their quick on/off control. Additionally, check valves prevent heartburn, while butterfly valves supply a lightweight option for controling circulation. Each valve type is created with details products and setups to endure the rough conditions commonly found in oil fields, making sure reliability and performance in operations. Recognizing these types is vital for efficient system administration.Valve Applications and Features

While numerous types of valves serve distinct objectives, their primary applications rotate around regulating circulation and stress within oil and gas systems. Shutoffs such as entrance, world, and sphere valves regulate fluid movement, making certain peak efficiency and security. Gate shutoffs are commonly utilized for on/off control, supplying minimal flow resistance. Globe shutoffs, on the various other hand, offer accurate circulation guideline, making them suitable for throttling applications. Round shutoffs are favored for their quick operation and limited securing capabilities. On top of that, stress alleviation shutoffs are essential for preventing system overpressure, safeguarding tools stability. On the whole, the proper choice and application of shutoffs improve operational performance, ensuring the dependable transportation of oil and gas through pipes and handling centers.Compressors: Enhancing Gas Transport

Compressors play a critical role in the reliable transport of gas, guaranteeing that it moves smoothly with pipes over cross countries. These gadgets boost the pressure of gas, permitting it to conquer have a peek at this website friction and elevation adjustments within the pipeline system. Furthermore, compressors help with the harmonizing of supply and demand, fitting changes in usage and manufacturing prices. Numerous kinds of compressors are utilized in the market, consisting of centrifugal, reciprocating, and rotating screw compressors, each offering distinct benefits based on the functional requirements. Normal maintenance of these compressors is important to make the most of efficiency and lessen downtime, eventually adding to a dependable gas transportation network. Their crucial function underscores the value of compressors in the total oil and gas facilities.Storage Tanks: Safe and Effective Liquid Monitoring

Effective transport of natural gas depends on numerous support group, among which is the appropriate management of tank. These tanks play a necessary role in safely having fluids, ensuring that operational efficiency is maintained while minimizing ecological risks. Constructed from resilient materials, they are created to endure high stress and destructive elements. Correctly sized and tactically situated, tank promote the smooth circulation of gas and other liquids, avoiding bottlenecks in supply chains. Regular maintenance and surveillance are imperative to find leakages or structural problems, promoting security and conformity with regulatory criteria. Inevitably, the effective management of storage space containers is important for the general honesty and reliability of the oil and gas market's fluid handling systems.

Pipeline Systems: Framework for Transport

Pipeline systems work as the backbone of the oil and gas sector, helping with the reliable transportation of hydrocarbons over substantial distances. These systems contain different elements, consisting of pipes, valves, pumps, and compressors, all diligently developed to guarantee smooth flow. The products made use of in pipeline construction, often steel or high-density polyethylene, are chosen for resilience and resistance to rust. Pipeline networks can span throughout land and water, connecting production sites to refineries and distribution. In addition, advanced modern used track loader technology makes it possible for real-time surveillance of flow prices and pressure levels, boosting functional performance. The tactical positioning of these pipelines lessens environmental influence while making best use of source access, therefore playing an important function in meeting power needs globally.Safety And Security Equipment: Making Certain Worker and Environmental Management

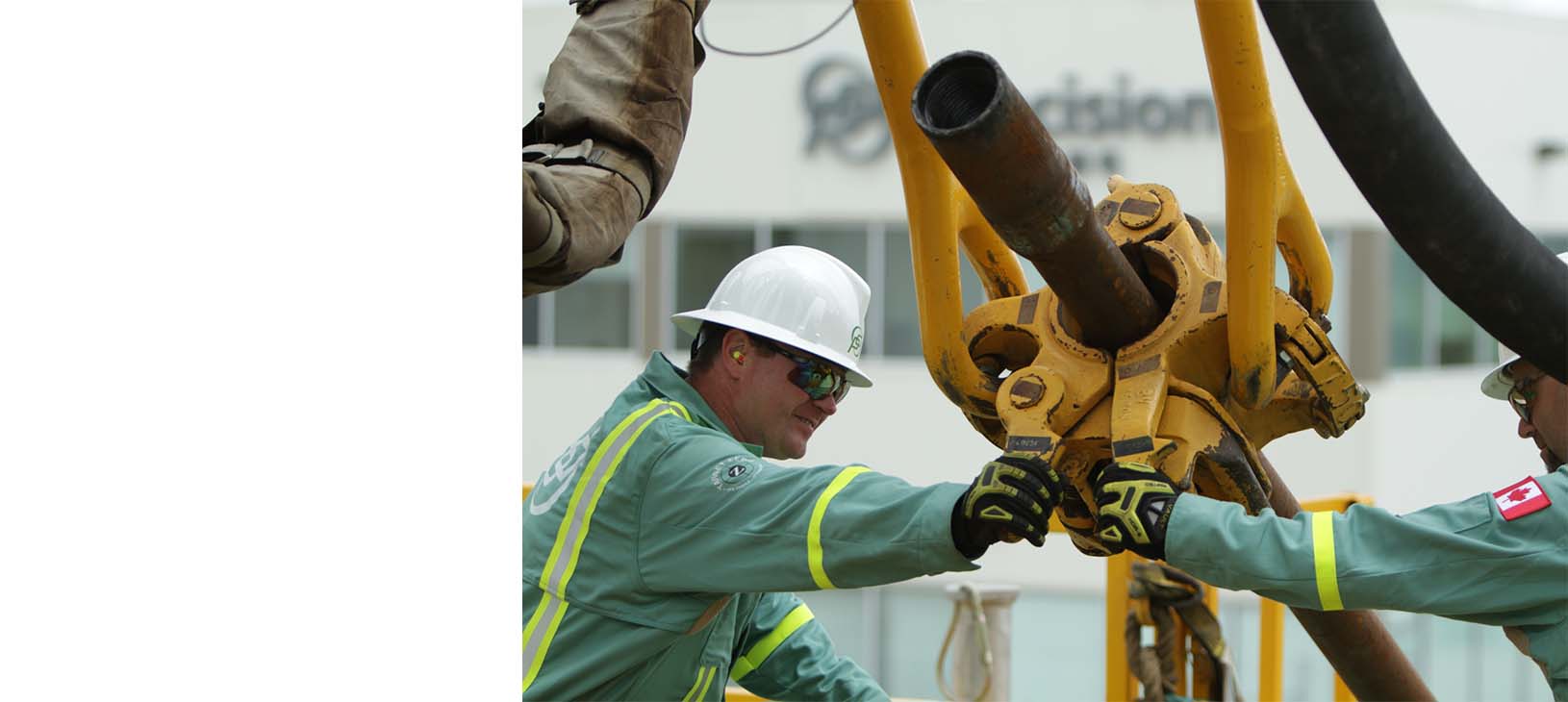

The procedure of pipeline systems, while important for energy transport, likewise provides significant safety and security obstacles for employees and the atmosphere. Safety and security tools plays a significant duty in minimizing these dangers. Personal protective devices (PPE) such as headgears, handwear covers, and non-slip footwear safeguards workers from physical threats. Additionally, gas detection systems keep track of for leakages, making sure that unsafe substances do not posture a threat to employees or the bordering ecological community. Emergency situation shutdown systems are imperative for rapidly stopping procedures during a crisis, avoiding prospective catastrophes. Spill containment products, consisting of absorbents and barriers, are basic for minimizing ecological influence. Overall, investing in all-encompassing safety and security equipment is vital for maintaining operational integrity and securing both employees and the setting in the oil and gas sector.

Frequently Asked Concerns

Just how Do I Select the Right Oil Field Equipment for My Project?

Picking the best oil area devices involves examining task requirements, budget constraints, and operational requirements. Think about elements such as equipment dependability, compatibility with existing systems, and the supplier's track record to assure peak performance and security.What Are the Upkeep Needs for Oil Field Equipment?

Upkeep requirements for oil area devices include normal assessments, lubrication, and timely fixings. Operators must additionally stick to maker guidelines, monitor efficiency metrics, and assurance conformity with security laws to enhance long life and efficiency.

How Can I Make Sure Compliance With Environmental Rules?

To assure conformity with ecological guidelines, companies should perform routine audits, apply best methods, buy training, maintain correct documents, and stay updated on regulations (Superior Rentals fusion machines). Collaboration with ecological firms can additionally improve adherence to guidelinesWhat Is the Ordinary Life-span of Pipeline Equipment?

The typical lifespan of pipeline equipment normally varies from 20 to 50 years, relying on variables such as worldly high quality, ecological problems, and upkeep techniques. Routine assessments can substantially influence long life and functional efficiency.Exactly how Do I Safely Carry Oil Field Equipment to Remote Locations?

Delivering oil field devices to remote areas requires careful preparation, including path evaluation, safeguarding licenses, making use of suitable vehicles, and making certain safety methods click to read are followed. Appropriate training and communication amongst staffs are important for effective transportation.Report this wiki page